MENU

KINDAI Technology

Founded in 1945, Kindai's main product, which has been manufactured with a wealth of experience and high technology in a wide range of fields cultivated over 75 years. Introduce the technology of Roll Slitter, Heat Cutting Machine (Slitter), Sewing Machine for Both Sides.

Technology of Roll Slitter

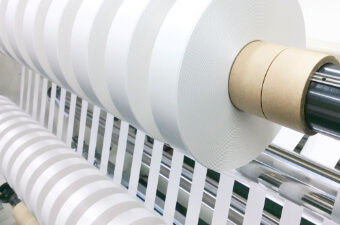

What is Roll Slitter?

Roll Slitter is Slitter that slits the material wound into a roll with a blade. It can be set on the display according to the width and number of cuts, so that beginner and women can operate it easily.

-

KINDAI Technology.01

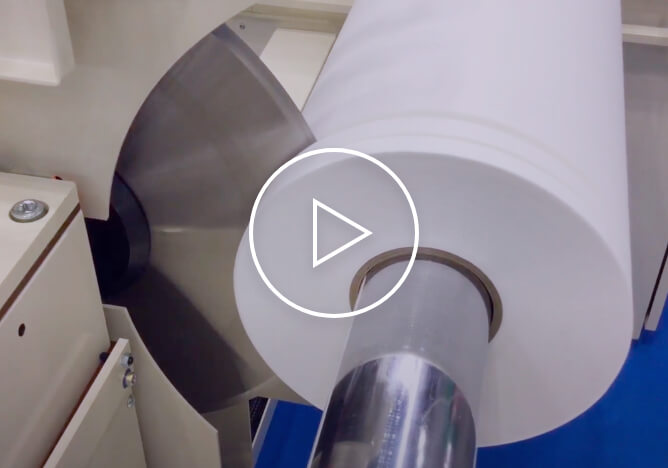

Blade and Roll

Women can operate it with peace of mind

The number of rotations and the direction of rotation of the blade and chuck are very important for slitting the material. Our Roll Slitter can freely adjust the rotation speed and rotation direction of the blade and chuck, and can perform slit processing under optimum conditions according to the material. Among them, one of the features is that the cutting forward speed of the blade can be adjusted by changing the gear in three steps. For example, when starting to cut a material, the cutting speed is slowed down, and then the material is cut at a high speed. When cutting the paper core or plastic core at the end, it becomes slow again. By shifting in 3 steps, it is easy to make slits according to the material and winding hardness.

-

KINDAI Technology.02

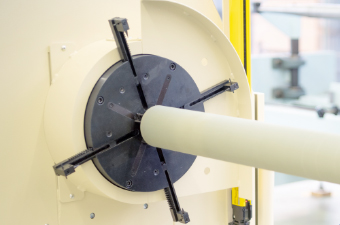

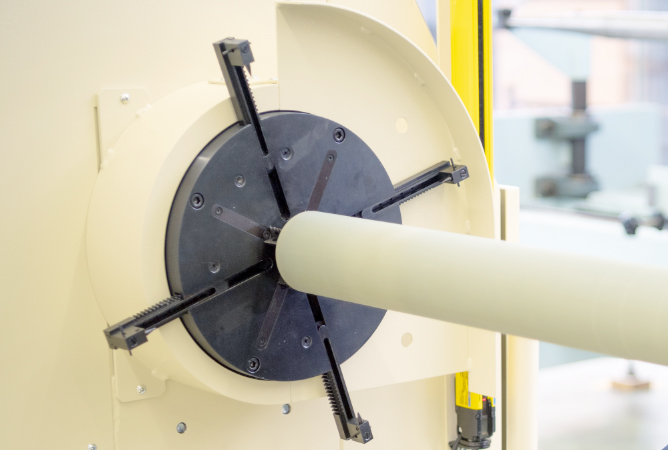

Chuck

Beautifully chucking the roll with constant pressure

The device that fixes the material is called a chuck. Our Roll Slitter chucks the inner and outer paper cores and the outer periphery with a constant pressure with inner and outer claws. The inner and outer claws are important to rotate the material at high speed and achieve stable slitting. If the material is not chucked properly, it may cause defects when slitting. However, since the pressure volume that chucks the material uniformly is installed as a standard specification, the pressure can be adjusted according to the material to prevent cut surface defects. Even if the outer diameter changes, the position of the outer claw can be adjusted with one touch, so workability is good.

-

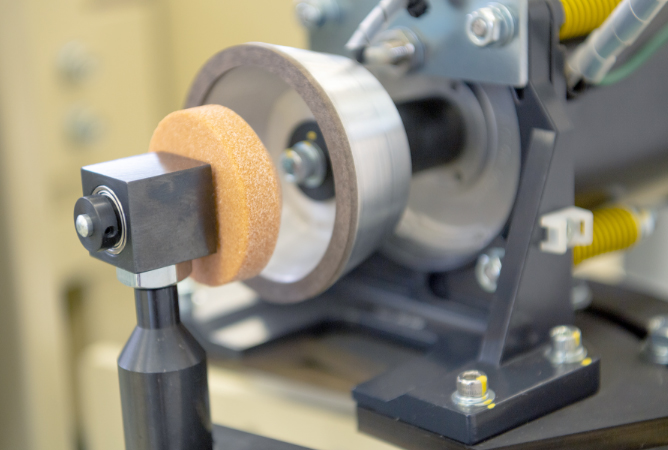

KINDAI Technology.03

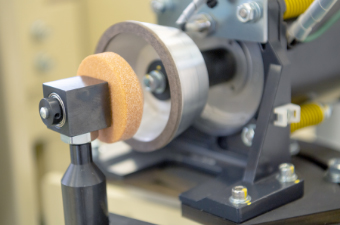

Grinding

The sharpness of the blade is the lifeline of the cut surface

When the cutting edge is worn, the sharpness of the material may become poor and "fluffing" or "double cutting" may occur. Our Roll Slitter is equipped with a grinding device, so you can easily grind the cutting edge without replacing the worn blade. Manual grinding can carefully grind the blade edge by manual operation, and it is effective when you want to adjust the blade edge to an acute angle or an obtuse angle. Since automatic grinding automatically performs the set number of grinding operations during automatic operation, it is effective when you want to perform efficient grinding without the need for fine adjustment. In addition to grinding blade, we also offer a wide variety of blade types such as blade material, blade shape, blade edge angle, etc. according to the material.

Roll Slitter is used in various industries.

-

Film industry

Functional films, PP/PE films, surface protection materials, reflective materials, etc.

-

Tape industry

Adhesive tape, double-sided/single-sided tape, masking tape, elastic tape, packaging tape, polyester tape, etc.

-

Nonwoven industry

Masks, taping, bandages, hygiene products, punch carpets, interior sheets, filters, etc.

-

Automotive industry

Carbon sheets, various interior sheets, etc.

-

Rubber industry

Bicycle tires, drive belts, zippers, various rubber sheets, etc.

-

Textile sewing industry

Via tape (clothes, slippers, shoes), various fabric materials, etc.

-

Leather industry

Synthetic leather, artificial leather, etc.

-

Paper industry

Wallpaper sheet, paper tube, cardboard, etc.

Technology of Heat Cutting Machine

What is Heat Cutting Machine?

Winds a roll with a roll-to-roll, by heat to the round blade of our original mechanism installed on multiple sheets, it beautifully welds without generating waviness on the cut surface and prevents fraying cleanly. Suitable for wiping cloths, curtains, banners, printed flags, belt cores, blanket edging tape, ribbon tape and mesh.

-

KINDAI Technology.01

Free Rotation Round Blade and Fixed Blade

Our blade unit is kind to the fabric

Compared with the fixed blade type, the free rotating round blade type designed by our company has the best feature that the welding surface is finished smoothly and heat cutting can be performed while suppressing burrs. Furthermore, by taking advantage of the characteristics of the free-rotating round blade, it is possible to heat cut and wind at high speed, and heat cutting can be done without applying excessive load or resistance to the material. A wide variety of blade angles are available, from acute to obtuse, so you can achieve a clean weld surface with the optimal blade according to the material. The feature of the fixed blade type is that it can perform heat cutting at higher temperatures than the free rotating round blade type.

-

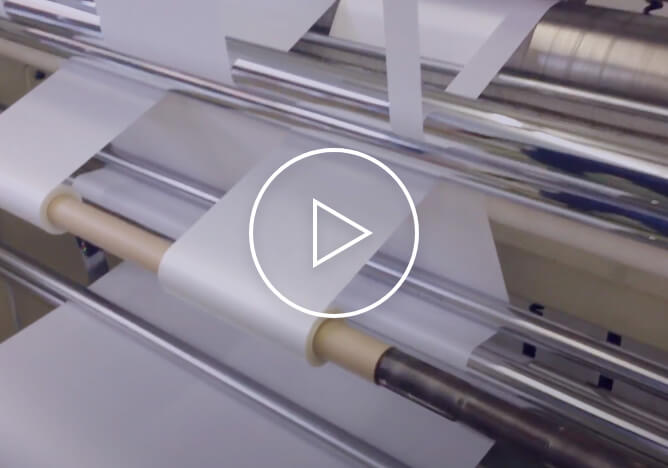

KINDAI Technology.02

Winding

Uniform tension control realizes beautiful winding

The strength of the tension control has a great influence on whether or not you can wind up cleanly. If the take-up tension is low, wrinkles will occur, and if the take-up tension is high, contraction or deformation will occur. In addition, since the winding is done with the upper and lower shafts, if the tension is not constant in the upper and lower sides, the heat cut width becomes uneven, which may cause wrinkles and slack. Especially after heat cutting, the amount of winding becomes unstable due to the influence of the welded surface, but since our heat cutting machine is equipped with a tension control, it is beautiful while maintaining a constant tension according to the change in winding diameter. Besides, the end surface will rise a little due to the influence of the amount of welding, but by installing our uniquely designed device, it is possible to wind up safely without worrying about the rise of welding.

Heat Cutting Machine is used in various industries.

-

Banner

-

Synthetic leather

-

Mesh filter

-

Curtain roll screen

-

Wiping cloth

-

Ribbon tape

What is Slitter?

Winds a roll with a roll-to-roll, slits it, and winds the roll with a specified number of winding meters is called a Slitter. Roll Slitter is a method of slitting the specified cutting width with a single blade along with the paper core. Slitter is a method of winding multiple rolls of raw material while slicing them into a roll. The feature is that you can achieve stable accuracy and quality because the winding length can be freely set and the continuous sheet can be slit. In addition, Slitter has three types of slit methods. It is possible to further pursue price, accuracy, and quality by performing slitting by selectively using the "Shear cut method", "Score cut method", and "Leather cut method" based on the material, cutting width, and processing conditions.

Relation between Slitter and Roll Slitter

Since Kindai has been producing both Slitter and Roll Slitter for many years, we can clearly understand the relation between the two products. Both have various features, but we distinguish the products we propose based on the needs of our customers. Especially in recent years, there is a growing need for operability and work efficiency, so the Roll Slitter that takes into consideration can easily set the cut width and number on the display and slits with stable quality. The biggest advantage of the Roll Slitter is that it requires no skilled operation or adjustment technology and can be easily operated by beginner and women. Slitter is the most suitable machine for those who place importance on productivity because of the ability to line up multiple blades and for those who want to slit a single continuous sheet, and who want to further improve quality. The slit method is completely different, but both products are the same as the machine that "slits the roll” and Kindai proposes the best machine for your needs as a professional Slitter manufacturer.

Technology of Sewing Machine for Both Sides

What is Sewing Machine for Both Sides?

Normally, only the right sewing machine is sewn, but our machine is also equipped with a left sewing machine and simultaneously sew both ears of the towel at the same time. By sewing simultaneously on the left and right sewing machines, you can achieve efficient and stable sewing.

-

KINDAI Technology.01

Sewing Machine

The first developed towel automatic sewing machine in Japan

By installing a left sewing machine, which is rare in the sewing industry, the left and right sewing machines sew three sheets of material simultaneously. The features of the sewing machine are that it can be sewn at the same time with the left and right sewing machines, so that it can be sewn efficiently and that uniform tension can be applied at the same time to prevent puckering and achieve stable sewing. There are many types of sewing machines, but by selecting a sewing machine suitable for the material, it is possible to sew various materials from thick sheets to thin sheets. In addition, our uniquely designed "thread breakage detection sensor" is also installed as standard specification.

-

KINDAI Technology.02

Stuck and Folding

Nonstop operation is possible with the stockpiling function

There are two types of material, J-Box type and U-Box type, both of which are characterized by being able to stock materials before sewing. When there is no more stackable material, the original fabric detection sensor operates in advance and automatically stops once at a position where it is easy to connect with new material. The storage side is temporarily stopped, but since a certain amount of material is stored, it is possible to continuously sew the material without stopping the automatic operation. In addition, after the sewing, a device that sorts the material neatly (folding) is installed as standard specifications, so it is considered so that it is easy to move to the next process. After sewing, it is possible to change to winding, cutting fixed-sized blades, cutting fixed-size nichrome wire.

Sewing Machine for Both Sides is used in various industries.

-

Towel

-

Blankets/sheets

-

Curtain

-

Carpet

-

Scarf

-

Container/Tent sheet

目次