MENU

Technology Information

Roll Slitter

- #Round blade

2020.07.06

Blade selection by industry pioneer of Slitter

There are two types of round blades for Roll Slitter: single-edged and double-edged.

High-quality and high-precision slit processing is realized by selectively using “single-edged” and “double-edged” depending on the material, winding hardness, slit width, etc. Both shapes have merits and demerits, and this time we would like to introduce the generally conceivable characteristics.

Table of contents

Round blade shape

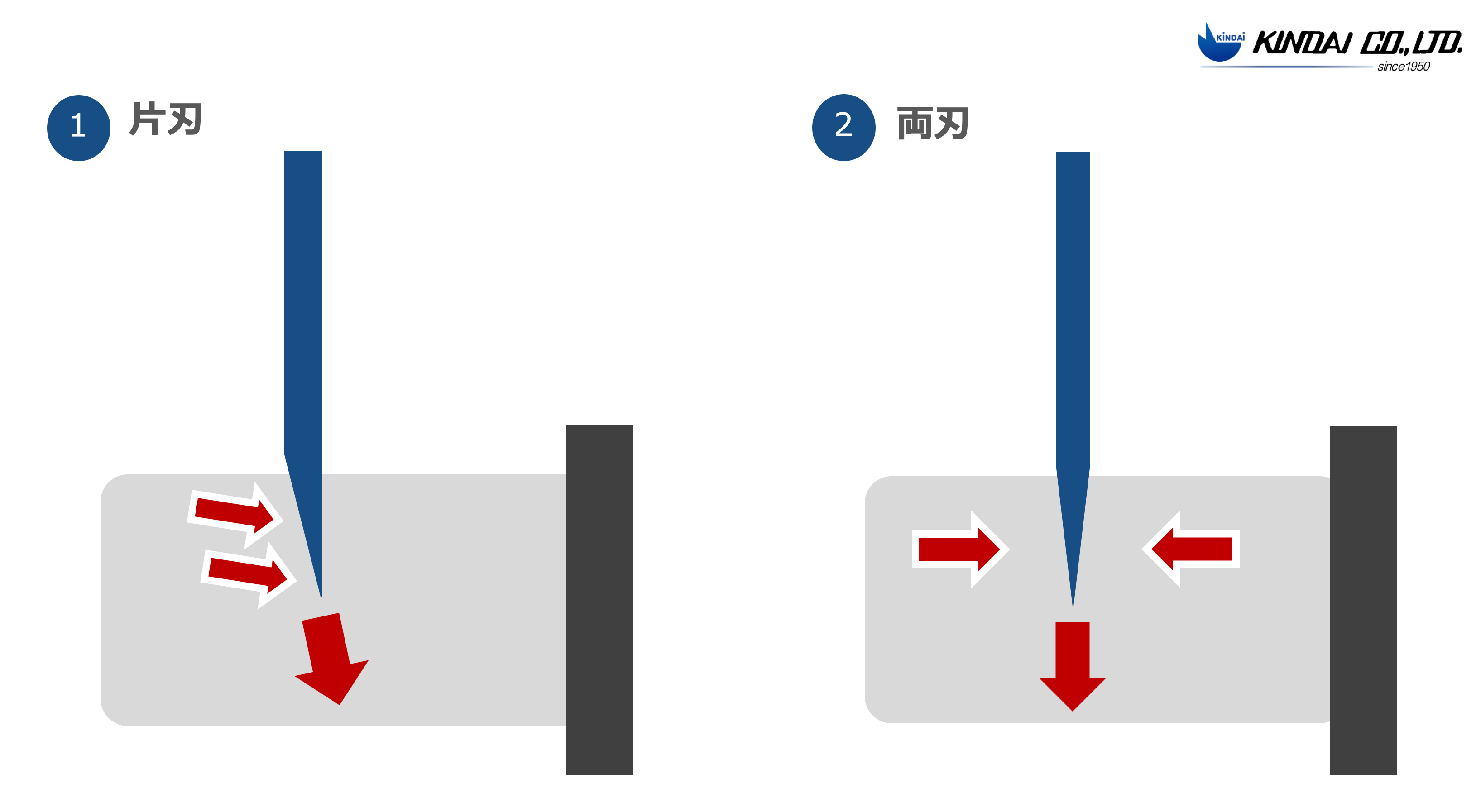

As you can see from the name about the difference in shape,

One-sided blade has a blade on one side

The double-edged blade has different shapes on both sides.

The cross section of the tool is shown below as a simple diagram.

Advantages and disadvantages of single-edged

Advantages of single-edged

Single-edged blades have sharper edges compared to double-edged blades, so they are overwhelmingly superior in sharpness and clean slit surface. Not only good quality, but also dimensional accuracy is higher than double-edged. We are also good at cutting thin widths (slice cuts) by taking advantage of the sharpness of the cutting edge.

Disadvantages of single-edged

Since the cutting edge is sharp, it is easily worn, and depending on the material to be slit, it is necessary to grind the cutting edge regularly. (Our products are equipped with a polishing device as standard equipment, so you can easily polish the cutting edge at any time.) Also, the large width of the slit causes a sharp load on the cutting edge, which causes a large load on the round blade. There is a possibility of losing the material, so single-edged blades are not suitable.

To summarize the advantages and disadvantages,

Merit

・The sharpness and cleanness of the slit surface are overwhelmingly superior.

・We are good at narrow slits

Demerit

・The cutting edge is easily worn

・Not suitable for thick slits

Advantages and disadvantages of double-edged

Advantages of double-edged

Since it has blades on both sides and the cutting edge has an obtuse angle compared to a single blade, the force on the material is applied evenly and it is superior in straightness to a single blade. It is the most suitable shape for slitting hard materials or heavy objects with winding hardness. In addition to that, straightness is also required when slitting thick widths, so it is possible to slit neatly using a double-edged blade. Another advantage is that the edge is less likely to wear because the edge angle is more obtuse than a single edge.

Disadvantages of double-edged

Since the cutting edge has an obtuse angle, it is necessary to add an option of the tool angle swing device when making narrow slits. (If you attach a blade angle swinging device, it is possible to make narrow widths and slits of soft materials that are not suitable.) Also, the finish of the cut surface tends to be slightly rough compared to the single blade, so the cut surface Double-edged blades are unsuitable for slits, where quality and precision are pursued.

To summarize the advantages and disadvantages,

Merit

・Ideal for materials with hard winding hardness and heavy objects

・Suitable for thick slits

Demerit

・Cut surface is slightly rougher than single-edged

・Not suitable for narrow slits

Round blade features list

| Single-edged | Double-edged | |

| Slit width | Thin is good | Thick is good |

| Winding hardness | Soft is good | Hard is good |

| Slit surface | ◎ | ◯ |

| Lifespan on blade | △ | ◯ |

*Comparison with standard specifications of our products.

To select the optimum round blade shape

The shape selection of the round blade greatly depends on the material, winding hardness and slit width. We have 75 years of experience since our founding, and we will select the best round blade for your material. In addition, we offer many types of blades such as round blade material, round blade shape and blade angle. Round blades are the “life line” when slitting, so we propose round blades that can perform slitting with higher quality and efficiency.